Low maintenance

Self fendering

Long service life

Easy handling and repair

SURFACE SUPPORT BUOYS

General surface support buoys are used extensively in single point mooring (SPM) systems, designed to withstand the severe & delicate operating conditions associated with offshore operations. Made out of closed cell PE/EVA foam, coated with resistant polyurethane skin ensuring the buoy will not absorb water even if the skin is damaged, increasing the life expectancy of the product and reducing the maintenance costs.

The main types of surface support buoys of Evergreen Maritime are:

- Cylindrical buoy

- Chain through support buoy

- Pick-up buoy

- Anchor Pendant Buoy

Comparison of Different Types of Buoys

| Type of Buoy | Structure Features | Application Range |

| Cylindrical Buoy | – Cylindrical shape, large size | – Navigation mark in waterways |

| – High buoyancy and stability | – Mooring buoy for vessels | |

| – Can be equipped with lights, radar reflector, or AIS | – Signal or warning buoy | |

| Chain Through Support Buoy | – Spherical or elongated body with central chain-through hole/pipe | – Supporting anchor chains and subsea pipelines |

| – Strong load-bearing capacity | – Offshore mooring systems | |

| – Provides even force distribution | – Reducing wear on chains and cables | |

| Pick-up Buoy | – Small,cylindrical, spherical or oval | – Marking the end of a rope or chain |

| – Lightweight and easy to handle | – Easy retrieval of lines | |

| – Bright colors for visibility | – Temporary or auxiliary use |

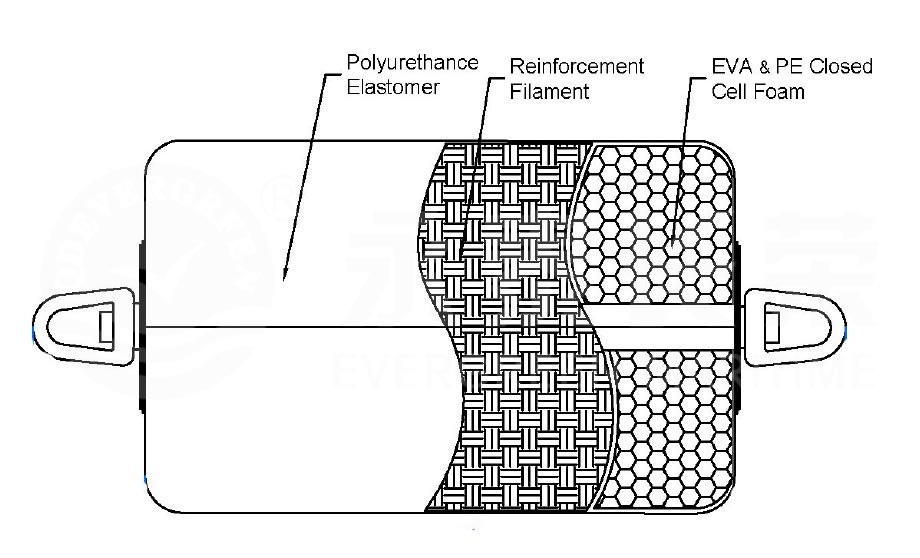

A. Closed cell resilient foam core, unsinkable design

General surface support buoys are made with highest quality closed-cell PE/EVA foam. This resilient foam makes the buoys self fendering with high absorption capacity. Even the skin was punctured, it is also unsinkable without absorbing water. With our unique laminating process, each foam core is integrited. The foam core will not be ruptured after long time service.

B. Tough nylon filament reinforced polyurethane skin

General surface support buoys’ skin is constructed of polyurethane elastomer which is reinforced with nylon filament. The polyurethane skin is the unique elastomer specifically used for offshore applications. Its high resistance to abrasion, fatigue and ultra violet degradation are significantly more durable.

C. Steel work and end assembly

Through central steel tube with longitudinal gussets and external load distribution flanges at each end, epoxy coated or hot-dipped galvanized, are encased in a closed-cell urethane foam central body. Optional pad eye, clevis eye, swivel, chain locking plate, single locking pin end fitting are available.

Regular size and performance

Cylindrical Buoys (YT-CB)

| Type | Buoyancy (kg) | Length of body (mm) | Diameter (mm) | Weight in air (kg) |

| YT-CB1000 | 1000 | 1550 | 1080 | 375 |

| YT-CB1850 | 1850 | 2000 | 1230 | 470 |

| YT-CB2250 | 2250 | 2000 | 1340 | 500 |

| YT-CB3200 | 3200 | 2000 | 1560 | 560 |

| YT-CB3900 | 3900 | 2000 | 1705 | 605 |

Chain Through Buoys(YT-CTB)

| Type | Buoyancy (kg) | Length of body (mm) | Diameter (mm) | Weight in air (kg) |

| YT-CTB1500 | 1500 | 2000 | 1195 | 520 |

| YT-CTB2750 | 2750 | 2000 | 1505 | 630 |

| YT-CTB3500 | 3500 | 2000 | 1680 | 750 |

| YT-CTB4500 | 4500 | 2000 | 1900 | 880 |

Pick-up Buoys (YT-PUB)

| Type | Buoyancy (kg) | Length of body (mm) | Diameter (mm) | SWL (tonne) | Weight in air (kg) |

| YT-PUB 90 | 90 | 665 | 515 | 1.2 | 42 |

| YT-PUB 225 | 225 | 914 | 690 | 16 | 120 |

| YT-PUB 400 | 400 | 914 | 900 | 16 | 155 |

| YT-PUB800 | 800 | 914 | 1150 | 16 | 180 |

Evergreen buoys have been successfully applied in Victoria Harbour, Hong Kong

Subsea Support Buoys

SUBSEA SUPPORT BUOYS

Evergreen subsea mooring buoys are specialized flotation devices deployed beneath the ocean’s surface, typically at fixed depths. They provide critical buoyant support in systems requiring long-term, stable underwater positioning.

Application field

Evergreen subsea mooring buoys are specialized flotation devices deployed beneath the ocean’s surface, typically at fixed depths. They provide critical buoyant support in systems requiring long-term, stable underwater positioning.

- Oceanographic monitoring

- Subsea instrumentation arrays

- Offshore oil and gas survey

- ROV & AUV

Advantages

- 1. Independently developed glass microsphere foam body, already proven in applications at 3,000 meters water depth, with a theoretical capability of up to 7,000 meters.

- 2. Flexible customization in a wide variety of shapes.

- 3. Stable and reliable performance

Performance of subsea buoyancy material

| Item | Unit | Value | |||

| 500 m | 1000m | 1500m | 4500 m | ||

| Density | g/cm³ | ≤0.4 | ≤0.45 | ≤0.5 | ≤0.60 |

| Compressive Strength | MPa | ≥5 | ≥10 | ≥15 | ≥40 |

| Hydrostatic Pressure | MPa | ≥5 | ≥10 | ≥ 15 | ≥37 |

| Water Absorption | % | <2 (5MPa,24h) | <2(10MPa,24h) | <2(15MPa,24h) | <2(40MPa,24h) |