Foam Filled Fenders

Evergreen-Maritime is the Leading Manufacturer of Foam Filled Fenders

Foam Filled Fender is a part of an unsinkable, tough heavy-duty fendering system for harbor, offshore and ship-to-ship applications.

Introduction

Brief Introduction

Evergreen Maritime foam fenders have different designs to meet various applications: Ever-Guard type (netless), Ever-Cushion type (netted), Small Shipboard type, and Rubber Foam Fenders.

Foam filled fender system is one kind of tough heavy-duty floating fenders system for harbor, offshore and ship-to-ship applications. Ever-Guard foam fenders are able to absorb 40% more energy than similar sized pneumatic rubber fenders, with relatively gently reaction force as compared to other marine fender systems.

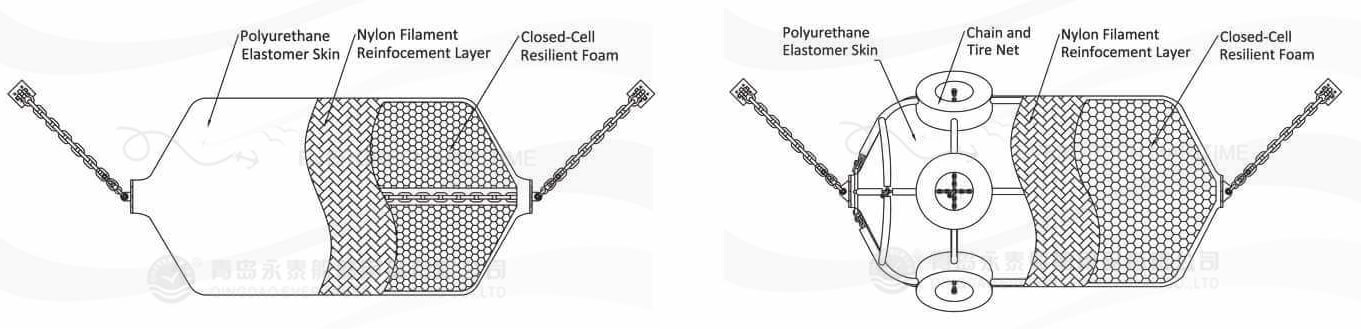

Foam filled fenders are constructed with closed-cell, energy absorbing resilient foam laminated layers, nylon filament reinforcement layer, tough polyurethane skin. This construction ensures the Ever-Guard foam filled fenders suit the most rugged working environments.

Pressure Test

Parameters

Product parameters

Evergreen Maritime foam fenders are fabricated with closed-cell resilient foam, with protective tough polyurethane elastomer skin (or tough rubber skin), reinforced with nylon filament. What’s more, protective chain and tire net are optional for Ever-Cushion foam fenders.

A. Foam filled fenders are filled with highest quality resilient closed-cell foam. This specific foam can provide high energy absorption with relatively low reaction force. Even the skin is punctured, it also is unsinkable without absorbing water. With our unique laminating process, each foam core is integrity. The foam core cannot be ruptured when compressed.

B. Ever-Guard and Ever-Cushion Foam filled fenders’ skin is constructed of polyurethane elastomer which is reinforced with nylon filament. The polyurethane skin is the unique elastomer specifically for fender applications. More thick filaments and elastomer are applied to both ends to better resist the defection and shearing force.

The typical PU skin color is black, orange, navy grey, or yellow.

C. Foam filled Fenders are comprised of through central steel tube and external load flanges distributed at each end. All end fittings are hot-dip-galvanized. Except the through central pipe, all longitudinal chains are joined to Clevis eyes at both ends of the fender.

D. Evergreen foam filled fenders incorporate chain and tire net. The chain and tire net design use heavy-duty hop-dipped-galvanized chain, fitted with heavy-duty ties at the net intersections. This chain and tire net carry the tensile load, minimize stress on the fender skin.

E. Chain and net used for the netted type Ever-Cushion type foam fenders.

F. Rubber Foam Fenders’ skin is protected by vulcanized rubber. It’s more tough and has higher performance.

| EVA Foam Core | |

| Property | Standard |

| Density | 58~70kg/m³ |

| Tensile strength | ≥414kN/㎡ |

| Elongation at break | ≥120% |

| Compressive strength | ≥ 140 Kn/㎡ |

| Water absorption | < 1 kg/㎡ |

| Working Temperature | -30 to +70°C |

| Reinforcement Filament | |

| Property | Standard |

| Material | 2520denier |

| Tensile strength | 230N |

| Elongation at break | 16% |

| Helix angle | 45~60 degrees |

| Filament spacing | <4mm |

| Polyurethane Elastomer | |

| Property | Standard |

| Hardness | 75~95 |

| Tensile strength | >13.8Mpa |

| Elongation at break | >300% |

| Tear strength | >32kN/m |

| Flexural life | >10000cycle |

| Abrasion resistance | >100NBS |

Packing & delivery

Safe and fast packaging and delivery process