Various Design Options

Color Options and Durability

Lightweight or Reinforced Wall

Optimized Shipping & Storage

Pneumatic Rubber Fender

–– Sling Type (Without Chain & Tire Net)

Sling-type pneumatic fenders without protective nets are ideal for small vessel ship-to-ship operations or dockside berthing under favorable mooring conditions. This type of fender features integrated eyelets for easy installation. Thanks to its lightweight design, handling and deployment are convenient and efficient.

Various Design Options

Rubber jackets are available for fenders up to 2.0 meters in diameter. These are commonly used on oil tankers, LPG carriers, and cruise ships due to their low reaction force and minimal risk of sparking upon contact with the hull.

Color Options and Durability

While black is the standard color for pneumatic fenders, navy grey, cream white, and red are also available as options. Qingdao Evergreen Maritime uses advanced rubber formulations to ensure that the fender’s color remains stable and consistent, even under harsh marine conditions.

Lightweight or Reinforced Wall

Lightweight fenders are designed for portability and ease of use, making them suitable for cruise ships and smaller boats. Sling-type fenders with increased wall thickness offer enhanced resistance to abrasion and shearing forces, extending their service life in demanding conditions.

Optimized Shipping & Storage

Sling-type pneumatic fenders are typically deflated and pallet-packed for container loading, significantly reducing shipping and storage costs.

Product Details

All raw materials are tested in accordance with ISO standard specifications.

Outer Rubber Layer

The outer rubber protects the internal layers from abrasion and external impacts. It is formulated to have high tensile and tear strength, capable of withstanding harsh environmental conditions and heavy-duty use. Standard color is black, with gray and cream white available upon request.

Inner Rubber Layer

The inner liner is a rubber membrane that seals and retains pressurized air inside the fender.

Reinforced Synthetic Tire Cord Layer

Reinforcement layers are made from high-strength synthetic tire cords, arranged at optimal angles to maintain internal pressure and evenly distribute stress, providing durable and efficient structural support.

At Evergreen, we use only rubber raw materials that have passed ISO-standard testing, ensuring superior strength, durability, and safety in every pneumatic fender.

| Test Item | Test method | Required value | |

| Outer rubber | Inner rubber | ||

| Before ageing | |||

| Tensile strength | BS ISO 37 | 18 Mpa or more | 10 Mpa or more |

| Elongation | BS ISO 37 | 400% or more | 400% or more |

| Hardness | ISO 7619 | 60 +/- 10 (durometer hardness test type A) | 50 +/- 10 (durometer hardness test type A) |

| After ageing | ISO 188 | Air oven ageing, 70°C +/- 1°C. 96 h | Air oven ageing, 70°C +/- 1°C. 96 h |

| Tensile strength | BS ISO 37 | Not less than 80% of the original property | Not less than 80% of the original property |

| Elongation | BS ISO 37 | Not less than 80% of the original property | Not less than 80% of the original property |

| Hardness | ISO 7619 | Not to exceed the original property by more than 8 | Not to exceed the original property by more than 8 |

| Tear | BS ISO 34-1 | 400 N/cm or more | No requirement |

| Compression set | ISO 815 | 30% (70°C +/- 1°C for 22h ) or less | No requirement |

| Static ozone ageing | ISO 1431-1 | No cracks after elongation by 20% and exposure to 50 pphm³ at 40°C for 96 h. | No requirement |

| NOTE: if the colour of the outer rubber is not black, the material requirements will differ from those in this table. | |||

test equipment

Electronic universal testing machine

3000m water depth pressure simulator

Five ton tensile testing machine

100 ton Tensile Testing Machine

800 ton Compression Testing Machine

Moving Die Rheometer, MDR

Rubber Ozone Aging Tester

Rubber Slicing Machine, Rubber Plastometer Sample Grinding Machine, Abrasion Testing Machine

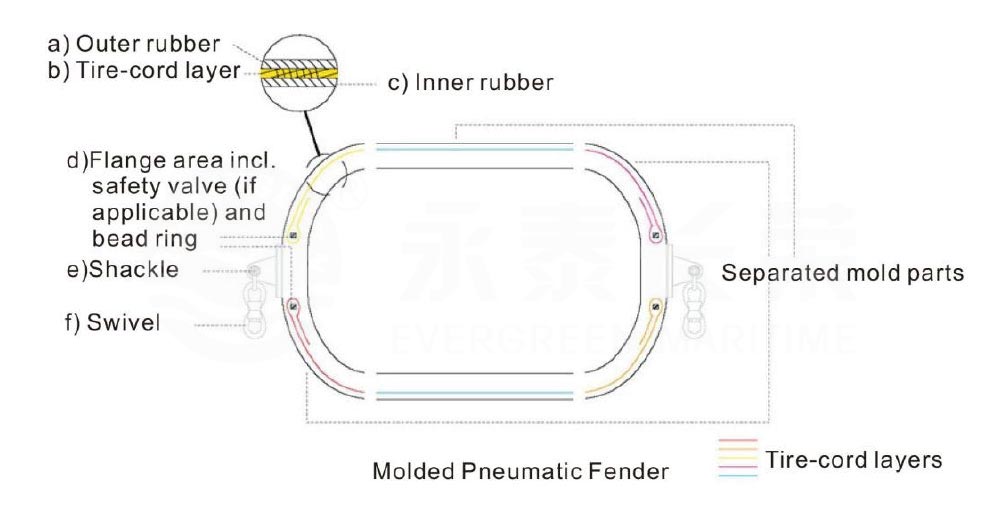

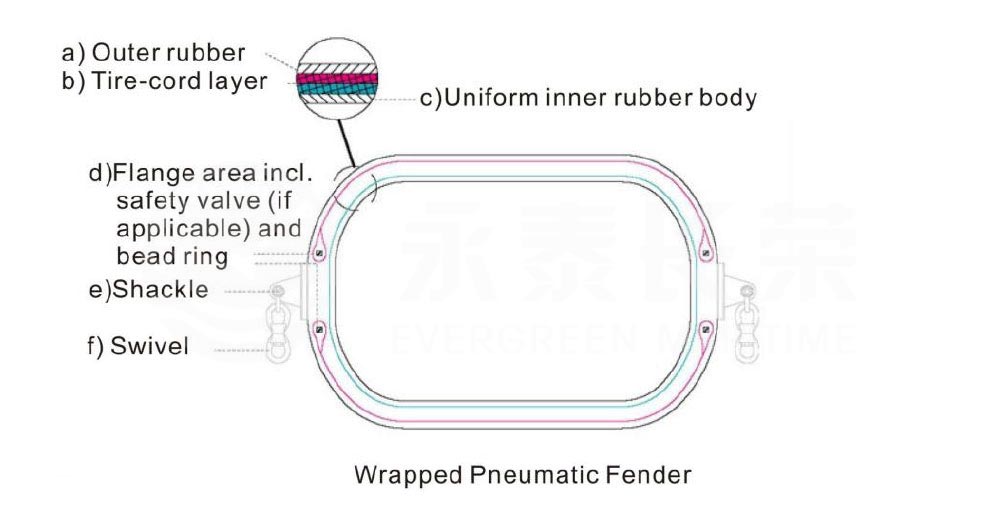

Warping vs. Mold Manufacturing Methods

The debate over which manufacturing method—warping (wrapping) or mold-forming—is superior for pneumatic fenders has been ongoing for many years. Different manufacturers claim advantages for their own processes. In fact, both methods hold a significant share of the current market, which clearly indicates that both types of fenders are capable of meeting industry demands.

Molded Pneumatic Fenders – Key Features:

- Smooth surface with tightly bonded layers

- Lighter weight and easy to fold – both a benefit and a drawback, as the thinner wall is more susceptible to punctures

- Difficult to repair on site; field repairs are challenging

- Lower yield rate and higher manufacturing cost

Warped (Wrapped) Pneumatic Fenders – Key Features:

- Surface may be uneven with minor imperfections

- Heavier, but more resistant to scratches and punctures

- Easier to repair on site

- Higher production yield and lower manufacturing cost

Compact. Flexible. Reliable.

Our sling type pneumatic fenders are designed for easy handling and versatile deployment, making them the ideal choice for small to medium-sized vessels during berthing operations. Engineered for performance without the bulk, they offer efficient protection where agility matters most.