In everyday port operations and ship berthing activities, marine fender systems are one of the most important safety components, even though they often receive little attention once installed. In real projects, the performance of Floating Pneumatic Rubber Fenders, Foam Filled Fenders, and other rubber fenders directly affects vessel protection, quay structures, and long-term operating reliability.

From practical experience, one of the first factors engineers consider is how the marine fender absorbs energy during vessel contact. Pneumatic Rubber Fenders, which rely on compressed air as a cushioning medium, are widely used in ports handling large vessels such as container ships, bulk carriers, and tankers. When properly inflated, these fenders provide high energy absorption while maintaining relatively low reaction force, helping reduce stress on both the vessel hull and port infrastructure.

However, performance in actual operation depends on more than just design data. Internal air pressure, environmental conditions, and berthing frequency all influence how a pneumatic fender system behaves over time. In high-traffic ports, different configurations such as Pneumatic Rubber Fender Net Type and Pneumatic Rubber Fender Sling Type are often selected based on installation requirements and protection needs.

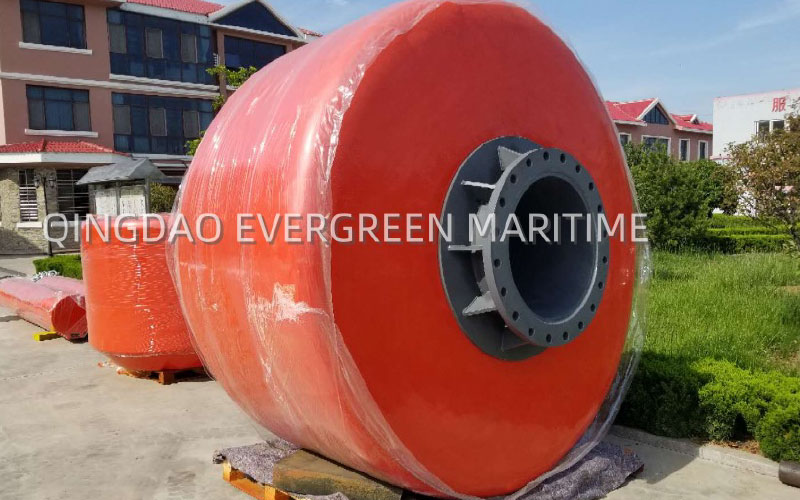

For projects where low maintenance and consistent performance are priorities, foam-based solutions are often considered. Unlike pneumatic designs, Foam Filled Marine Fenders do not depend on air pressure, which eliminates the risk of deflation during service. Their closed-cell foam core and durable outer skin allow them to maintain buoyancy and impact resistance even after long-term exposure to harsh marine environments.

In some specialized berthing areas, rotating protection systems such as Donut Foam Fenders are also applied to provide continuous vessel guidance and protection. These designs are commonly used where vessels need to move along the berth while remaining protected throughout the operation.

In many cases, engineers compare pneumatic fenders, foam filled fenders, and traditional rubber fender systems based on actual site conditions rather than theoretical performance alone. Factors such as vessel size, tidal variation, wave conditions, and installation method all play a role in determining the most suitable marine fender solution. There is no single fender type that fits every application.

Understanding these practical considerations helps project planners make better decisions during the fender selection stage and avoid unnecessary maintenance or replacement costs later. With long-term experience in manufacturing and supplying marine fender systems, Qingdao Evergreen Maritime continues to provide reliable solutions and practical insights for ports and offshore projects worldwide.