Introduction

In recent years, a number of extremely low-priced marine airbags and pneumatic rubber fenders have emerged on the market. While these products may seem attractive due to their price, they pose significant risks in terms of quality and performance. Below are the main reasons behind their low pricing:

Reason 1: Use of Recycled Rubber Instead of Natural Rubber

The market price of natural rubber is generally more than 10,000 RMB per ton higher than that of recycled rubber. Many low-cost airbags and fenders use partially or fully recycled rubber to reduce costs, which significantly compromises the physical properties of the rubber.

According to ISO14409-2014 and GB/T33487-2017 standards, the tensile strength of the outer rubber layer must exceed 18 MPa. Products using recycled rubber often fail to meet this requirement and are therefore considered substandard.

Moreover, due to the poor weather and aging resistance of recycled rubber, surface cracks often appear within 3 to 6 months. In contrast, Evergreen Maritime products show no surface cracks for over 3 years even under long-term outdoor exposure, significantly outperforming generic market products.

Reason 2: Use of Polyester Fabric Instead of Nylon Fabric

To further cut costs, many low-price products use polyester fabric (PET) instead of nylon fabric (PA). Though similar in appearance, their performance differs greatly:

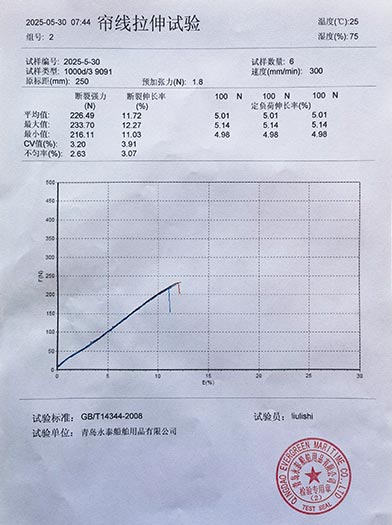

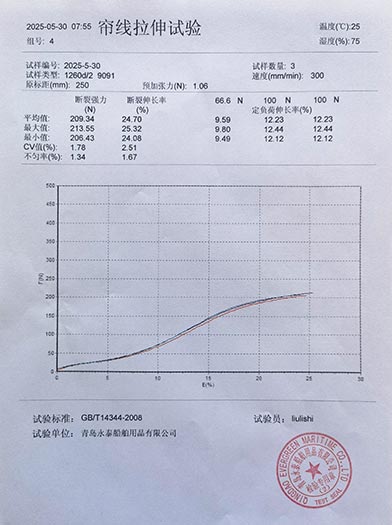

Adhesion Strength: Nylon adheres to rubber with a bond strength of over 258N, while polyester only reaches around 160N, making delamination and bulging more likely.

Elastic Recovery Rate: Nylon has a recovery rate of approximately 98%, whereas polyester typically ranges from 70–80%, making it less structurally stable.

Flex Fatigue Resistance: Nylon offers over 10 times the bending fatigue resistance of polyester, making it more suitable for stress-bearing applications.

Material Cost: Nylon fabric costs more than 6,000 RMB per ton higher than polyester.

Thus, using polyester instead of nylon results in serious flaws in lifespan, safety, and performance.

Reason 3: Use of Patching Process Instead of Integrated Wrapping

Low-cost products often adopt the ‘patching process,’ where rubberized fabric is cut into rectangular and trapezoidal shapes and layered manually. While labor- and time-saving, this method presents several issues:

– Uneven structural strength, with stress concentrated at patch joints.

– Vulcanization requires wrapping with water cloth to prevent cracking, resulting in a rough surface.

– Irregular appearance and shorter service life.

In contrast, Qingdao Evergreen Maritime insists on using the ‘integrated wrapping process,’ where fabric is wound in a continuous manner. Each two layers cross at a 15–25 degree angle, forming a dense, high-strength structure. This method requires no water cloth wrapping and yields a smooth, attractive appearance with enhanced consistency and reliability.

Reason 4: Skimping on Materials by Reducing Fabric Layers

Some low-cost manufacturers deliberately reduce the number of fabric layers, compromising the product’s pressure resistance and durability, thereby posing serious safety risks.

Reason 5: Lack of Qualification and Testing Equipment

These extremely low-priced products often come from uncertified small factories. They may purchase quality system certificates rather than earn them, and lack even basic inspection equipment. Their production process relies entirely on experience and “gut feeling,” with no capability to conduct systematic performance testing before delivery. Furthermore, these factories often lack support from relevant industry certifications and technical standards.

Conclusion: The Hidden Cost of Low Prices

Low-price products often reflect a ‘one-shot deal’ mentality — there’s no lowest, only lower. What seems attractive in price often conceals quality pitfalls. When issues arise, such manufacturers tend to shirk responsibility or even disappear, leaving no room for after-sales support.

When purchasing marine rubber airbags and fenders, it is essential to choose professional manufacturers with a reputable brand, proper qualifications, and complete testing capabilities to ensure true safety and economic efficiency.