In daily port operations, the real performance of a marine fender becomes apparent only after repeated vessel contacts. While design data is important, long-term behavior under actual working conditions is what truly matters for pneumatic fenders, foam filled fenders, and other marine protection systems.

For Floating Pneumatic Rubber Fenders, performance largely depends on proper air pressure and operating conditions. When maintained correctly, pneumatic fenders provide excellent energy absorption and flexibility, allowing them to adapt to different vessel sizes and berthing angles. This adaptability is one of the main reasons pneumatic fenders remain widely used in large commercial ports.

However, in high-frequency berthing areas, regular inspection becomes an important consideration. Changes in pressure, environmental exposure, and repeated impact can all influence how a pneumatic rubber fender system performs over time. Selecting the correct fender type and configuration at the beginning can help reduce maintenance workload later.

Foam Filled Marine Fenders behave differently in long-term use. Because their closed-cell foam core does not rely on air pressure, their performance remains stable even after extended service. This makes foam filled fenders a practical choice for projects where reliability and low maintenance are more important than flexibility.

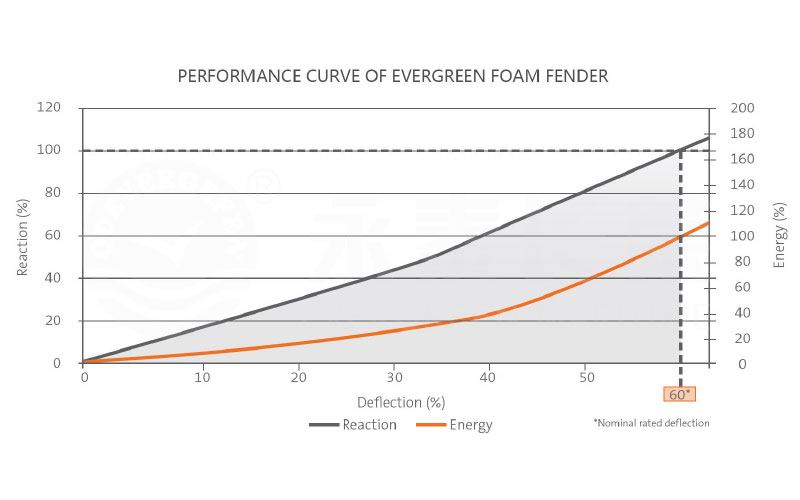

The compression performance curve of polyurethane foam fenders and rubber floating fenders is nearly linear. This means that the increase in reaction force and energy absorption is uniform, without any sudden spikes or turning points, which is more friendly to the safety of the ship’s hull. The tolerance for docking operations is also greater.

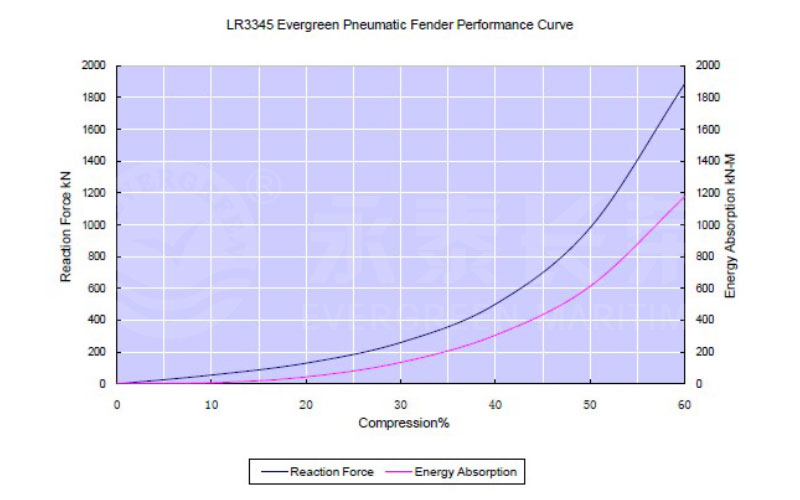

The compression performance curve of inflatable fenders is nonlinear. When the compression rate reaches 50%, the reaction force and energy absorption increase sharply. When the compression rate exceeds the maximum allowable 60%, it may impact the safety of the ship’s hull. Therefore, docking conditions need to be strictly controlled, and compared to rubber floating fenders, the operational tolerance is smaller.

In some applications, traditional rubber fenders are still used for basic protection needs, especially in smaller berths or low-impact zones. Each fender type offers a balance between energy absorption, reaction force, installation complexity, and lifecycle cost.

From a practical standpoint, there is no universal solution for all berthing scenarios. Evaluating vessel characteristics, site conditions, and operational frequency helps determine the most suitable marine fender solution. With years of experience supplying marine fender systems worldwide, Qingdao Evergreen Maritime continues to provide dependable products and technical support for diverse marine environments.