ISO 17357-1:2014 Certified

Long Service Life

Superior Safety

Product Advantages

Our pneumatic rubber fenders are ISO 17357-1:2014 compliant and DNV-GL type approved. They’re made from premium, non-recycled materials with an optimized structure and a safety factor exceeding 5:1, ensuring excellent performance and a long service life in harsh marine environments.

ISO 17357-1:2014 Certified

Evergreen pneumatic rubber fenders are fully compliant with the ISO 17357-1:2014 standard, from raw materials to manufacturing processes. The products have obtained DNV-GL type approval and can be certified by all major IACS classification societies upon request.

Long Service Life

Manufactured with premium-grade raw materials and strictly no recycled rubber, Evergreen pneumatic fenders feature an optimized internal structure and a reinforced, wear- and puncture-resistant outer layer. These features ensure reliable performance even in the most demanding marine environments.

Superior Safety

Designed with a safety factor exceeding 5:1, Evergreen pneumatic fenders offer exceptional reliability and operational flexibility, making them suitable for a wide range of working conditions.

High-Pressure Floating Pneumatic Rubber Fender

The high-pressure floating pneumatic rubber fender is a highly effective anti-collision solution widely used in marine environments. Constructed with an outer rubber layer and filled with compressed air, the fender floats on the water’s surface and functions as a powerful shock absorber during ship-to-ship (STS) transfers and ship-to-dock (STD) berthing and mooring operations.

Pneumatic fenders offer significant energy absorption capacity while exerting low surface pressure on the hull, minimizing the risk of damage. Additionally, their self-floating design, lightweight structure, and ability to be deflated and folded for easy transport and storage make them increasingly popular. As a result, pneumatic fenders have become the preferred choice for protecting vessels such as large oil tankers, LPG/LNG carriers, offshore platforms, bulk carriers, and a variety of floating structures, as well as for use in major ports, docks, and harbors.

Ideal for most ship-to-ship and ship-to-dock operations, especially under complex and harsh conditions. The chain and tire net provides added protection and durability, making it suitable for demanding marine environments.

Best suited for operations under stable berthing conditions, or in scenarios where weight restrictions apply. Lightweight and easy to handle, it offers reliable performance without the added net structure.

Designed for vessels with deep drafts or underwater berthing points, such as submarines, catamarans, semi-submersible platforms, and other similar applications. The vertical configuration ensures optimal protection below the waterline.

Product Specifications

Available sizes Φ500 ×1000L - Φ4500×12000L

Performance of P50 pneumatic fenders with popular sizes

| Nominal Size Diameter x Length | Initial Internal pressure | Guaranteed Energy Absorption (GEA) | Reaction Force at GEA | Hull Pressure at GEA | Safety Valve Setting Pressure | Testing Pressure |

| (mm × mm) | (kPa) | (kNm) | (kN) | (kPa) | (kPa) | (kPa) |

| 1000 × 1500 | 50 | 32 | 182 | 122 | – | 200 |

| 1350 × 2500 | 50 | 102 | 427 | 130 | – | 200 |

| 2000 × 3500 | 50 | 308 | 875 | 128 | – | 200 |

| 2500 × 5500 | 50 | 943 | 2019 | 148 | 175 | 250 |

| 3300 × 6500 | 50 | 1814 | 3015 | 146 | 175 | 250 |

| 4500 × 9000 | 50 | 4752 | 5747 | 146 | 175 | 250 |

Performance of P80 pneumatic fenders with popular sizes

| Nominal Size Diameter x Length | Initial Internal pressure | Guaranteed Energy Absorption (GEA) | Reaction Force at GEA | Hull Pressure at GEA | Safety Valve Setting Pressure | Testing Pressure |

| (mm × mm) | (kPa) | (kNm) | (kN) | (kPa) | (kPa) | (kPa) |

| 1000 × 1500 | 80 | 45 | 239 | 160 | – | 250 |

| 1350 × 2500 | 80 | 142 | 561 | 170 | – | 250 |

| 2000 × 3500 | 80 | 430 | 1150 | 168 | – | 250 |

| 2500 × 5500 | 80 | 1317 | 2653 | 195 | 230 | 300 |

| 3300 × 6500 | 80 | 2532 | 3961 | 191 | 230 | 300 |

| 4500 × 9000 | 80 | 6633 | 7551 | 192 | 230 | 300 |

Full-size pneumatic fenders performance data are available on request.

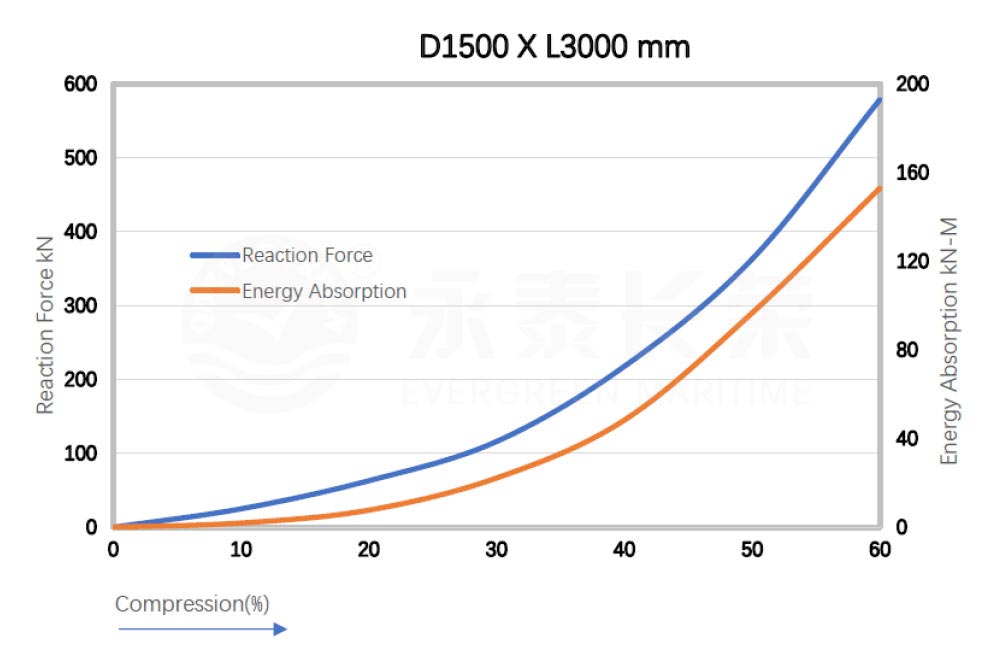

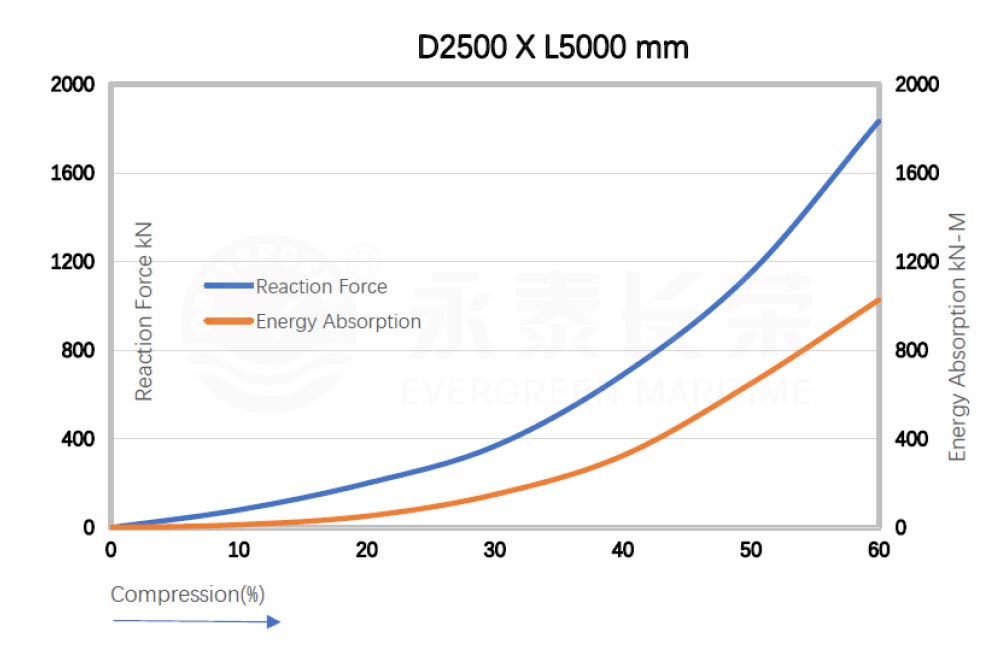

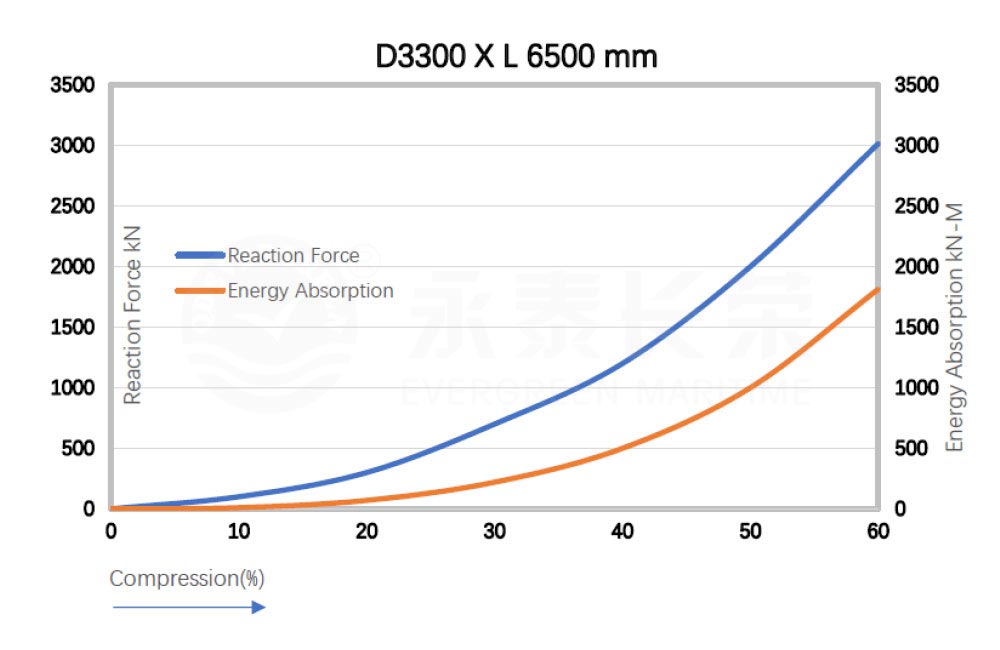

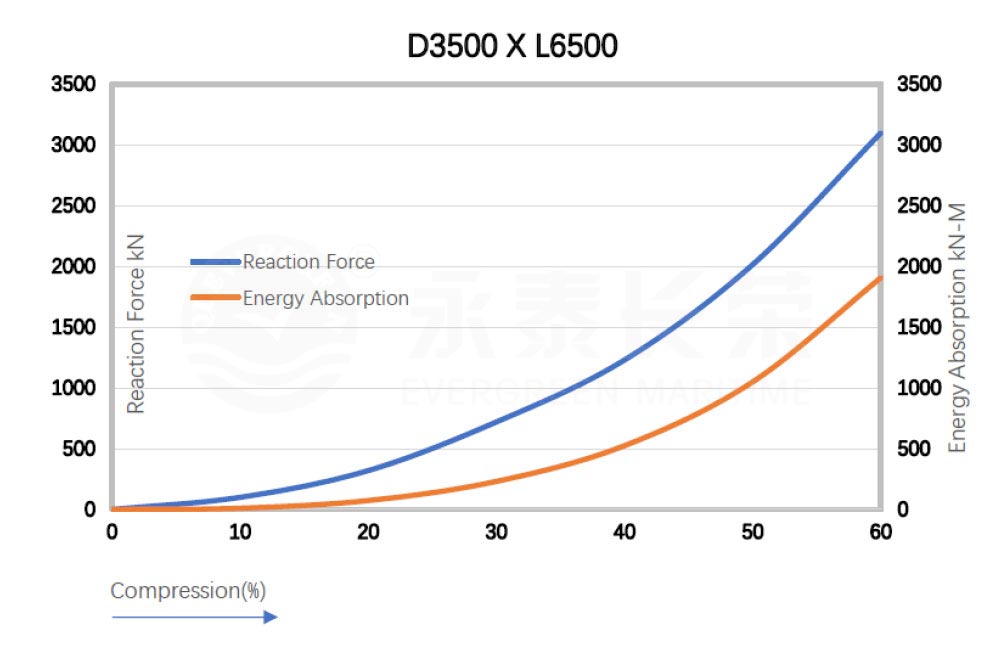

Performance Curve

Performance curves of reaction force and energy absorption for Evergreen Pneumatic Rubber Fenders are acquired by basically a static compression, a constant slow compression speed of 0.001m/s. However, during actual ship berthing operations, the Pneumatic Rubber Fenders are dynamically compressed at speeds over 0.05m/s.

Evergreen researched the effect of compression speed against the static rated values on reaction force and energy absorption. The result is that in actual ship berthing conditions those values are about 20% higher compared to those of static compression.

Below pictures show performance of some standard sizes of Evergreen pneumatic fenders under static compression.

Installation of inflatable fenders

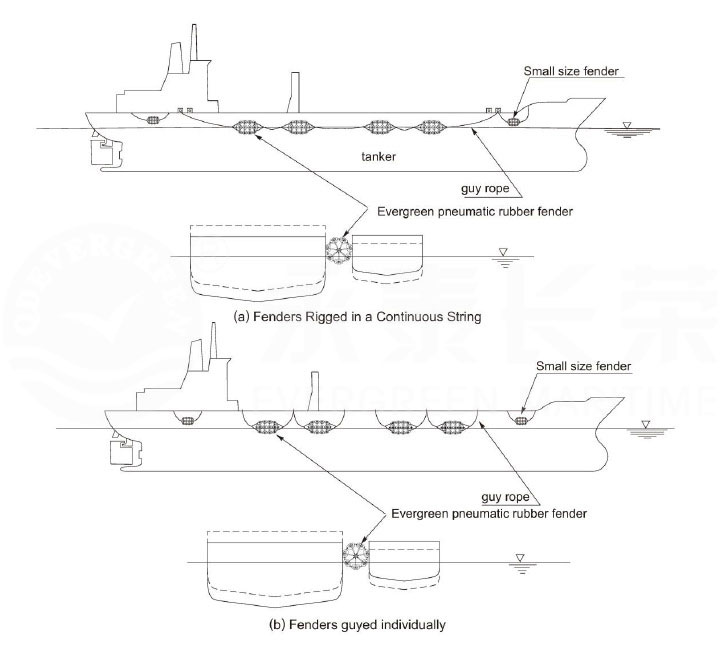

Ship-to-Ship Operation

For the light duty ship-to-ship operation, two contact points are enough. But for the heavy duty Ship-to-Ship operation, 1 or 2 extra pneumatic fenders should be used to increase the safety. These fenders are used as the primary fender to absorb the berthing energy, and keep proper stand-off distance between two ships. Meanwhile, two or more small-size fenders can be hung on the ship hull as the secondary fender.

The pneumatic fenders should be hung by guy chains or guy ropes, which should be selected depending on the different size and weather condition. Evergreen-Maritime pneumatic fenders are supplied with two end shackles that connect the fender body with guy chains or guy ropes.

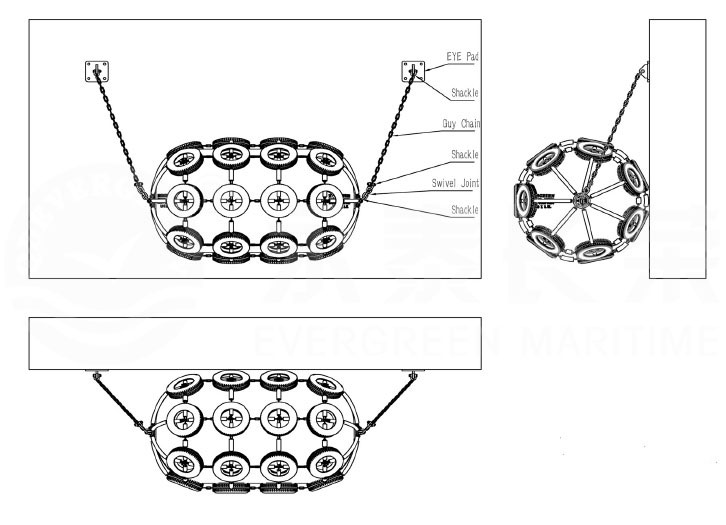

Ship-to-Quay Operation

Pneumatic Fenders are often used for the ship-to-Quay operation because of its excellent performance. The typical installation type is like the follow figure.

The pneumatic fenders are anchored with quay by the guy chain and shackle. Meanwhile the pneumatic fender can float on the water surface depends on the change of tide.

At both ends of the fender, first shackles, then swivel joints, followed by a further shackle should be installed. A guy chain or guy rope is secured to the outer shackle. The swivel joint prevents twisting of the guy chain or wire.

Rubber fender should be in a state of plane contact, as shown below, even when it is deflected

Application Cases

- Case Name: Myanmar LNG Power Plant Project Pneumatic Fender Supply

- Country: Myanmar

- Client: CNTIC VPOWER

- Products: Marine Pneumatic Rubber Fenders

- Time: February and August 2020

CNTIC is the joint business of Hong Kong-listed VPower Group and China National Technical Import & Export Corporation. The venture company for the investment in, development and operation of three power projects in Myanmar with an aggregate contract capacity of 900MW.

Invited by CNTIC VPOWER, in Feburary 2020, Evergreen Maritime offered the first batch pneumatic fenders with 4pieces 3300×6500 mm, 4pieces 3300×4500 mm and two baby fender 1000 mmx 2000 mm for the LNG carriers berthing and STS operations.

Then in August, the second batch pneumatic fenders were supplied for those LNG carriers by Evergreen Maritime again, with four baby fenders 1000×2000 mm and four big size fenders 3300×6500 mm.

Evergreen Maritime is proud of his distribution to Myanmar major projects will further alleviate local power deficit to support local economic development and enhance people’s living standard.

Customer feedback

Client Feedback from CNTIC VPower

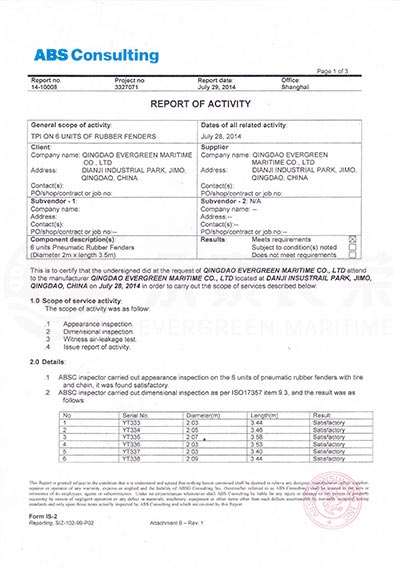

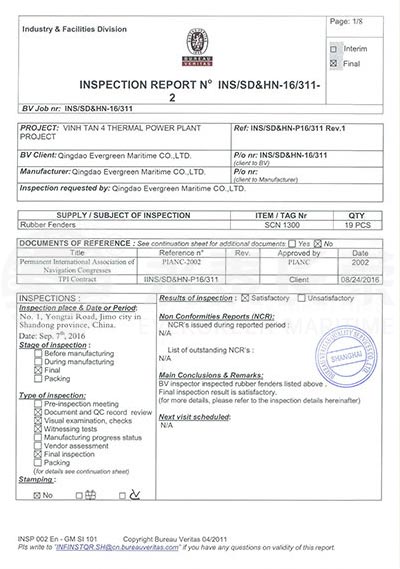

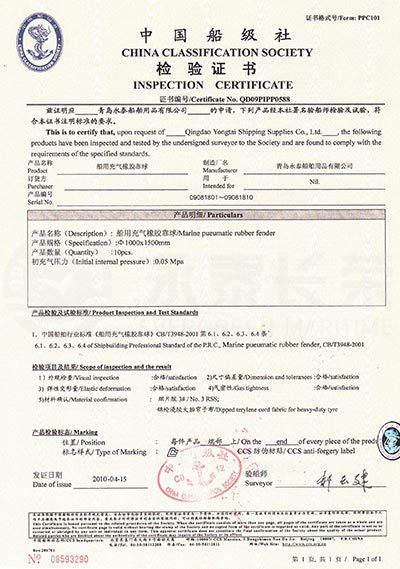

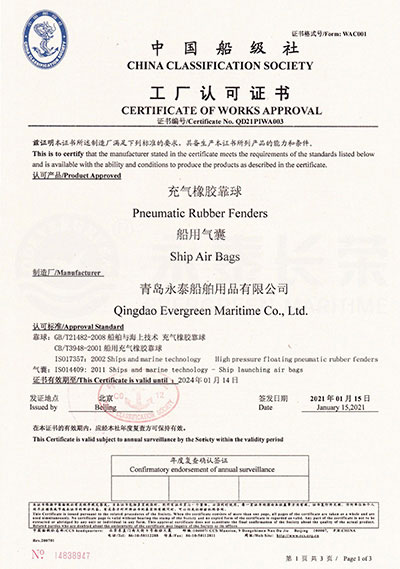

Certification and Standards

ABS Certificate for Evergreen fenders

BV Certificate for Evergreen fenders

CCS Inspection Certificate

CCS Type Approval Certificate

DNV-GL Type Approval Certificate

Docking video

This video demonstrates the safe and efficient ship berthing process using Evergreen Maritime’s High-Pressure Floating Pneumatic Rubber Fender. Witness how these fenders effectively cushion impact between vessels and quays, protecting hulls and structures while ensuring superior performance in various conditions.

Regular Inspection & Professional Service

Qingdao Evergreen Maritime One-Stop Fender Maintenance Solution

Qingdao Evergreen Maritime has implemented a standardized regular inspection system, offering professional and efficient one-stop maintenance services to clients worldwide. Our service scope includes routine inspection of pneumatic fenders, safety valve replacement, and comprehensive maintenance support.

During on-site visits, our experienced service engineers not only resolve customer issues promptly but also provide practical guidance on the proper use and maintenance of pneumatic fenders. Meanwhile, valuable customer feedback is collected and communicated to our production team, helping to continuously enhance product quality and improve user satisfaction.

The photos below show Qingdao Evergreen Maritime service engineers performing maintenance and inspection work for a pneumatic fender client in Italy.